T.D.A 3050 Pumpkin Seed Machine

TDA - 3050 EUROPE Pumpkin Seed Extractor is designed to harvest pumpkin seeds in the shortest time and with the highest yield. By adapting to variables such as climate, soil structure and seed typehelps farmers easily overcome any adverse conditions.

-

Overview

-

Product Details

-

Technical Details

-

Gaeri

Highlights

Precision Machining: Adjustable, specially designed for thin-shelled pumpkin seeds two batur systems is found.

Clean Product: Cleaner and smoother kernels are obtained thanks to the pallets with adjustable screen pressure.

Dual Function: With and without shell offers the possibility to harvest pumpkin seeds with a single machine.

Easy to Use: Maintenance is quick and practical thanks to the zonal lubrication lighters.

Automatic Sensor System: When the seed tank is full warns the operator.

Ease of Washing and Maintenance: Machine with water tank easy to clean after use and clogging of the sieves is prevented.

Safety and Resilience: Stone catching system, weeding brush and stone cover and protects the machine.

Efficient Posalama: Pumpkin pulp pulp distributor that distributes homogeneously in the field creates a clean workspace.

Road Safety: Air brake and lighting systems provides safe transportation.

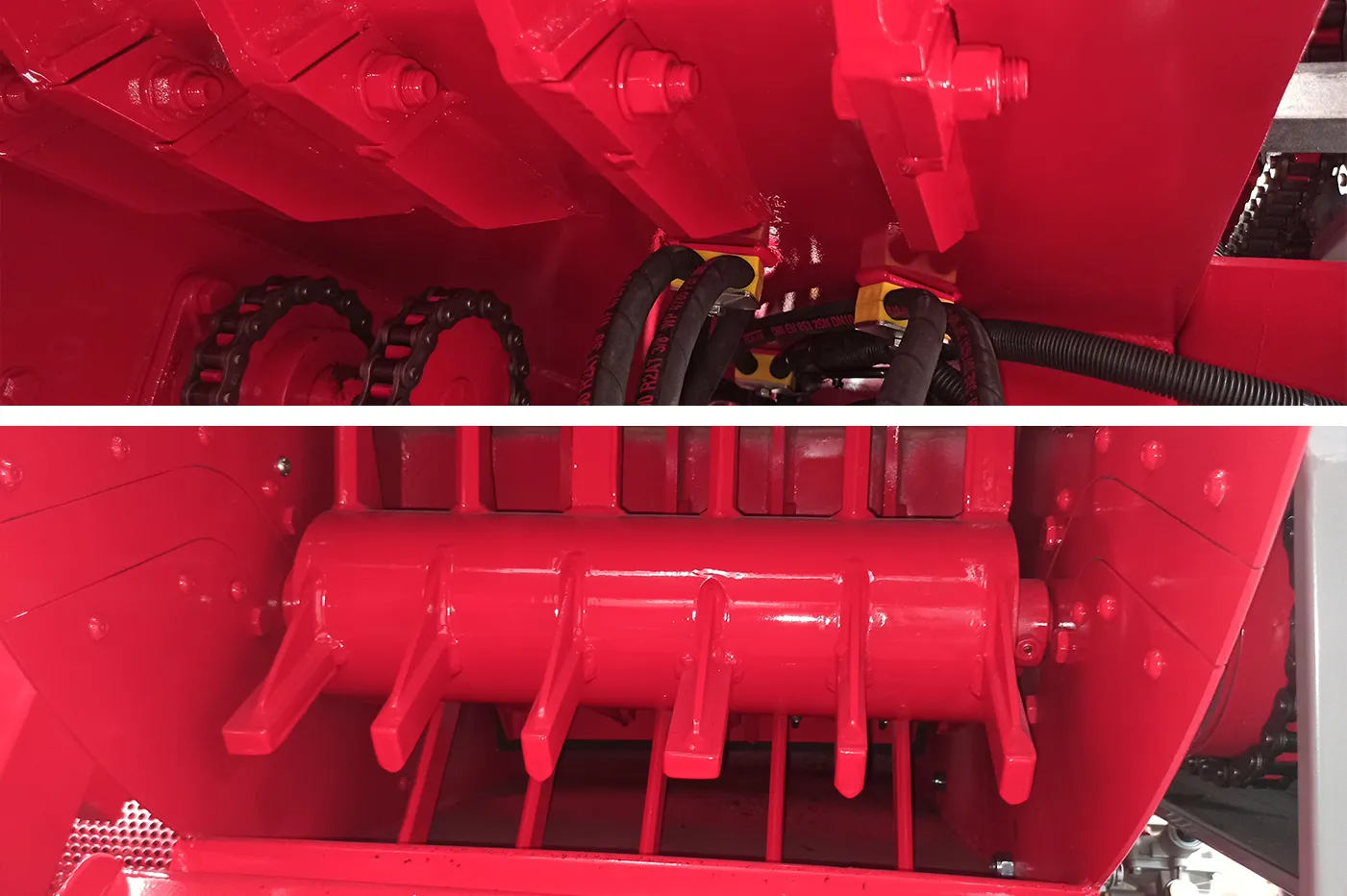

Cleaning drum sieve sheet change feature

The cleaning drum is bolted to the chassis body.

In this way, the sieve sheet can be easily changed according to different types and sizes of grains.

In addition, the sieve sheet, which wears out over time in the maintenance operation, is easily and in accordance with the original.

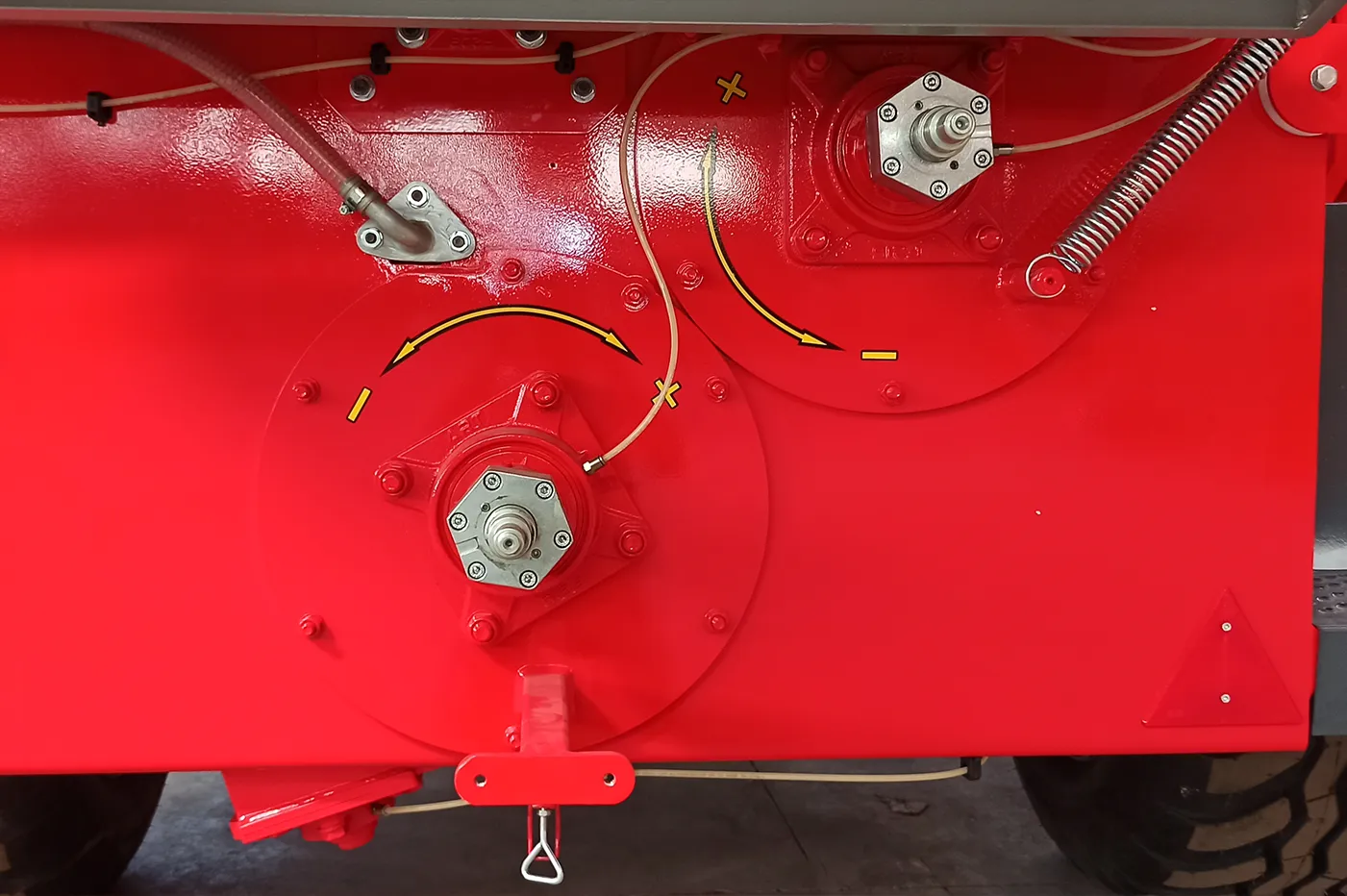

Adjustable batur system

Due to the very thin shell of pumpkin seeds, there are 2 adjustable batur systems designed to produce a very sensitive and clean product during processing. Adjustable batur system cleaner pallets can increase or decrease the pressure on the sieve according to the cleanliness and surface quality of the kernel. At the same time, it allows the harvesting of shelled and unshelled pumpkin seeds, which are different from each other, with a single machine.

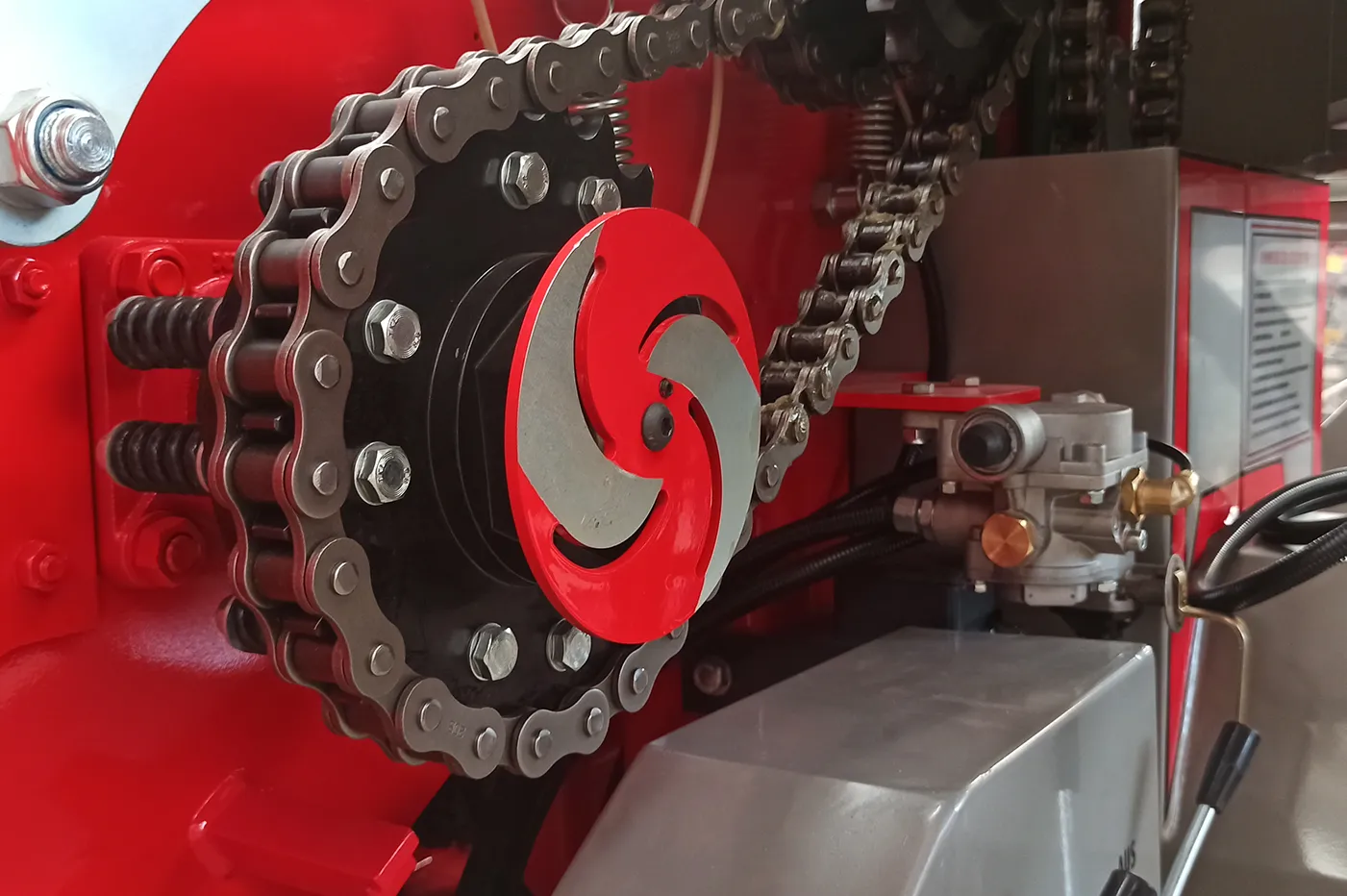

Cleaner and beater pallets

The pallets used for kernel separation are all food safe.

Stone catching lining system

There is a stone catching lining system to prevent the stones in the field from damaging the machine. Stones are caught before entering the machine.

Stone receiving cover

It allows the stones caught by the pads to be easily removed from the crusher chamber.

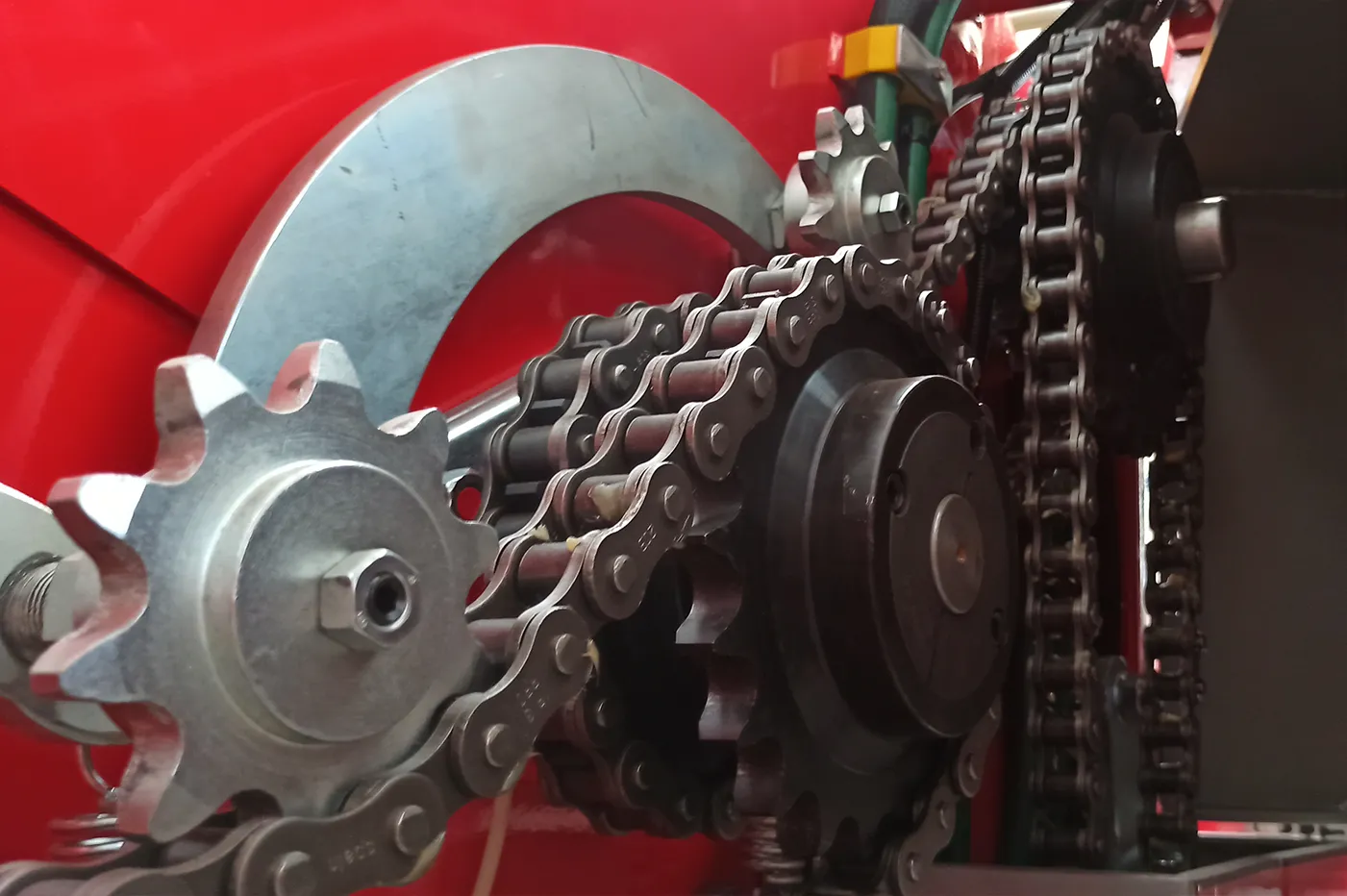

Shredding system

The shredder cylinder and blades are made of wear-resistant material and provide easy part replacement thanks to screw mounting.

Spring tensioning system

Since the chains used for power transmission can creep over time, the clutch and tensioning process is provided automatically by using spring tensioners on the gear chains.

Spiked ball gourd alignment guide

Thanks to the bearing pipe attached in front of the spiked ball, it rotates on the soil, reducing friction, allowing the weeds to come out and the pumpkins to get on the spiked ball.

Weed cleaning brush system

By preventing weeds from entering the machine, it helps the machine to operate at full capacity.

Changing property of ball studs

The spikes that allow the pumpkins to get stuck in the machine in the field can be deformed over time due to bad terrain conditions.

The spikes are screwed, not welded, to the ball body, making them easily renewable.

Core unloading system

Thanks to the hydraulically adjustable discharge auger, it discharges quickly at the desired height.

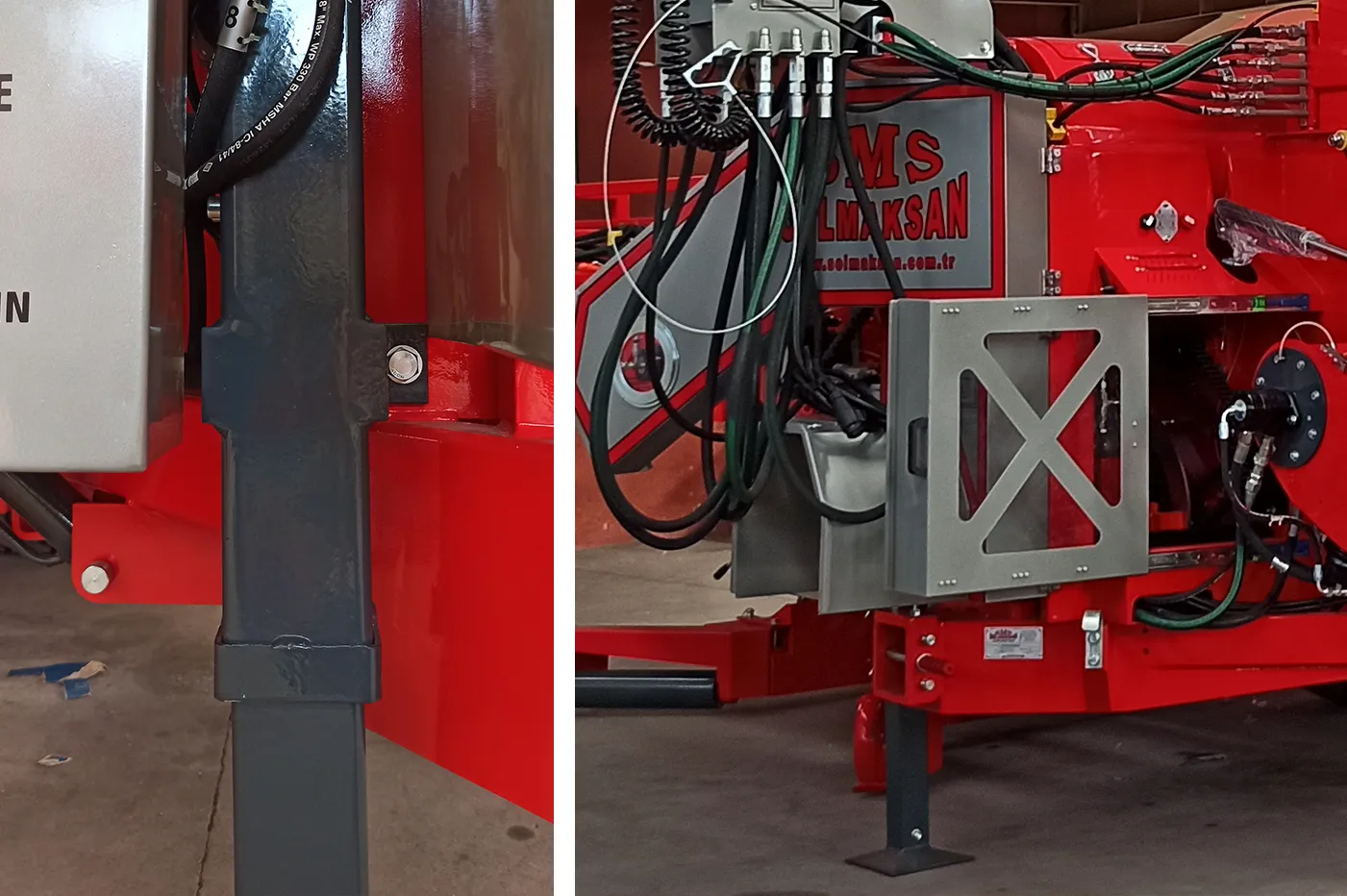

Hydraulic kirko

The hydraulic kirko makes it easy to detach the machine from the tractor and attach it to the tractor.

Water tank

Due to the fibrous structure of the pumpkin seeds, hardening on the screen allows the screen to lubricate itself faster and reduce friction in order to prevent overheating of the scraper pallets and damage to the seeds.

It allows the user to wash the machine for maintenance with a hydraulic water pump that can be added upon request.

Technical Details

| Seed separator length | 3050 mm |

| Seed separator diameter | 560 mm |

| Cleaning (two units) drum length, each | 2400 mm |

| Cleaning drum diameter | 380 mm |

| Length, general | 5185 mm |

| Length, overall (excluding trailer tongue) | 4445 mm |

| Height, general | 4000 mm |

| Width (Working position) | 4370 mm |

| Width (Transport position) | 2482 mm |

| Weight | 5300 kg |

| Operating capacity | 1-1.2 ha/h |

| Seed tank storage (approx.) | 1600 kg |

| Maximum seed discharge height | 3200 mm |

| Power | min 75 KW / 100 HP |

| Hyphen size | 500/50 – 17 |

Product Gallery